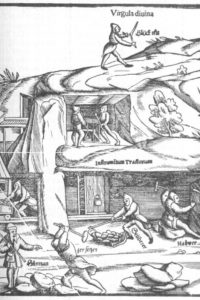

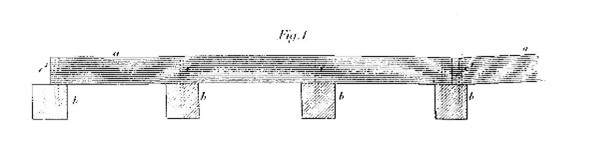

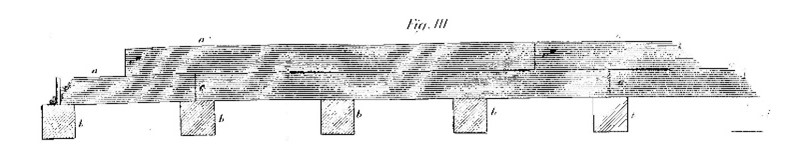

It may be strange to experience, but wooden rails have been in use for nearly 400 years, while the iron or steel flat bottom rails that are now common will not have their second centenary until 2030. Those wooden rails have changed a bit over time, although their function has been to carry the weight of the vehicles and to guide those vehicles all along. The oldest depictions of it in Cosmographei and De Re Metallica (both around 1550, so mid-16th century) shows wooden rails in Central European mine galleries on which sleds and carts were pushed and driven. In it ores, coal and stones were transported outside the mine. In the rough and intensive operation, the wooden rails quickly deteriorated and that was improved by pinning a second rail on it, which was usually made of harder wood and was therefore more durable. Central European mines became exhausted and the miners spread across Europe. That is how they arrived in England with their knowledge of mine transport. In the 17th century we see that the wooden tracks were extended beyond the mines and often widened. The wagons were then also enlarged, drawn by horses or self-driving (and also braked!) in case the track went downhill, and that track was used to transport the products from the mine and sometimes from the processing industry (coal, ore, iron) to canals or rivers for further transport. This system developed in Great Britain in the 18th century into a system of (often) public railways of hundreds of miles. The driver rode his cart upon it, paid toll, and used the track. There was then a plank on the wooden rail to keep the wagons in track. The wear of the wooden rails became a problem that was initially solved by nailing cast iron plates, which, however, often broke due to their brittleness. In 1767, Reynolds made low U-shaped cast iron rails that were nailed onto the wooden ones. Yet after that the wooden rails were replaced by cast iron in all kinds of models. In 1805 there was a wrought iron rail, which was not to be liked because it was too narrow and the wheels wore too hard. After John Birkinshaw succeeded in rolling wrought iron rails in 1820, this process was quickly improved and a short time later the cast iron rails disappeared completely. In the United States, however, wooden rails for public railroads remained in use until the fourth quarter of the 19th century because the wood was so cheap there that the cost of replacement was irrelevant. However, the wear resistance was greatly improved by nailing wrought iron plates upon it. In Great Britain other versions of wooden carrier rails with a rolled wrought iron wear rail have been tried, with very limited results. The wooden (carrier) rail experienced a renaissance when horse tramways sprang up on both sides of the Atlantic. A large number of wrought iron wear profiles have been developed for use on the wooden support rails. The transition to steam and electric trams at the end of the 19th century marked the definitive end of the wooden rail, except for a while in a “war version” on Singapore Island in World War II.

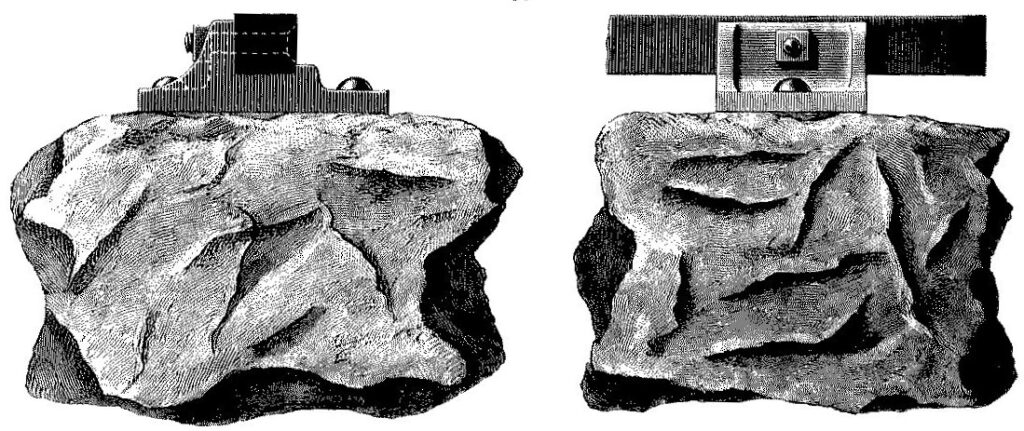

When it became clear through the reinforcement of the wooden rails with cast iron strips and “support rails” that the cast iron had limitations (susceptibility to fractures) but also possibilities, rails were made entirely of cast iron. A large number of shapes were developed. L-shaped rails were made that usually, but not always, lay on the ground and used wheels without flanges, later also on the locomotives. The shape of the rails kept the vehicles “on track”. Then we see a transition to rails on which wheels with flanges had to be used, a shape that quickly gained the upper hand. The name “edge rail” comes into use for this. Rail lengths were usually on the order of 1 yard (90.5 cm). If supports were used, which was usually the case, they were also at that distance. Only 3 yard long rails had two intermediate supports. When steam locomotives were developed from 1804, with significantly higher axle loads than coal wagons, the brittleness of the cast iron became an increasing problem. Nixon’s experiment with his forged rail in 1803 had come just in time, but unfortunately failed because the rail’s running surface turned out to be too narrow. With the use of granite rails introduced on the Dartmoor tramway in 1820, things didn’t get much better. Certainly that material cannot be denied great brittleness! The view of useful rails becomes much better when iron rails can be rolled, which John Birkinshaw succeeded in that same year 1820.

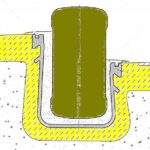

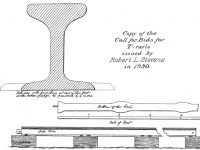

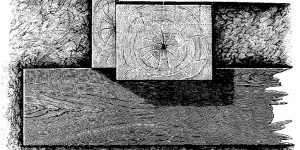

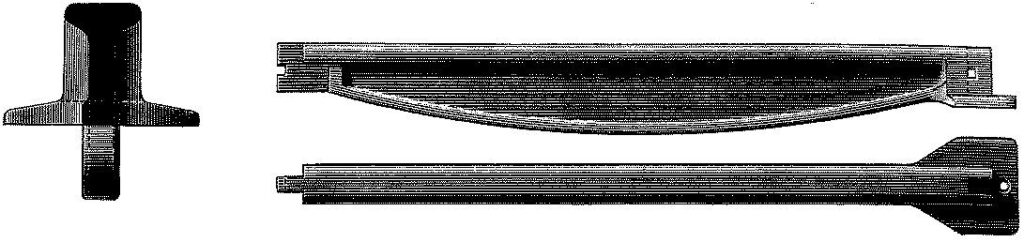

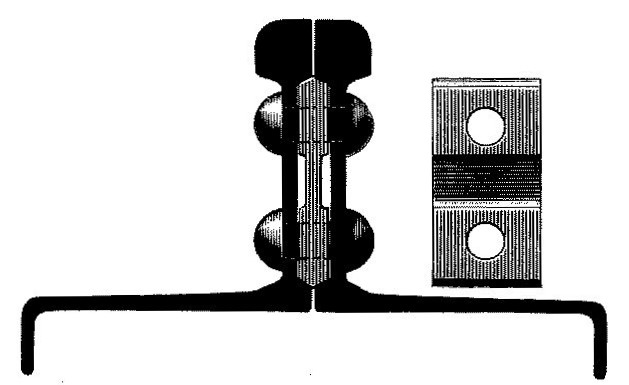

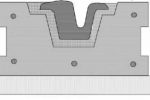

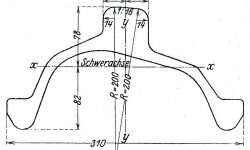

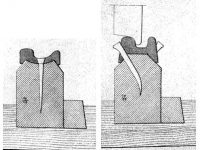

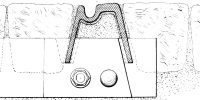

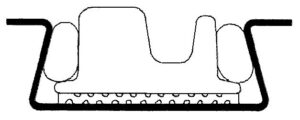

The first rolled iron rails were of the “bulb” type, T-type with the top of the T being the running surface and the bottom being wedged in cast iron chairs. Despite the high cost of the seats and the frequent tapping of the keys, this system has been able to last for a relatively long time in many countries. The rolled rails were just in time to be used on the public railways built and spread in Britain during the 1820’s and in continental Europe in the 1830’s. And of course that meant that many started to consider how the untold large quantities of railway that were to come could be carried out better and cheaper. A series of rail shapes was developed. The spire was kicked off by the American Robert Stevens who in 1830, on his way to Europe, designed the flat bottom rail that was introduced in Europe by the Irish Huguenot Charles Vignoles shortly afterwards and whose name was associated with this type of rail ever since. It is this rail that has basically settled the case and is virtually the only one in use worldwide today. It will certainly have contributed to its success that the flat bottom rail could be easily attached to wooden sleepers and no expensive cast iron chairs were required. Then in 1831 followed the bridge rail intended to be used without longitudinal or cross sleepers, just like the Reynolds’ rail from 1835 and also in 1835 the double-headed rail, which did require seats again. Barlow provisionally closed the list in 1849 with a heavy rail section that could be placed directly on the ground. In the course of the 19th century, numerous designs – largely applied – were intended to achieve special purposes, such as the easy replacement of worn-out railheads, the replacement of wooden sleepers with metal structures, adaptations for pavements which were of great importance to city tramways. Some names here are Hartwich, Paulus, Demerbe and Haarmann. Subsequently, the flat bottom model remains quietly in use for a long time, until in the last quarter of the 20th century attempts are again made to achieve certain advantages with new designs. The Nikex block rail system was developed especially for tramway tracks in Hungary in 1974, Lesley introduced a V-shaped embedded rail in 1991, and contractors Heijmans and KWS launched the Eria track embedded in cork rubber in 2005. For railways we see Hanker in 1922 with a high hollow rail for laying directly on the ballast bed and the English rail contractor Balfour Beatty in 2002 with BBest, using a system invented by Charles Penny with an almost rectangular rail profile that has to be pressed into a glass reinforced plastic channel. The latter brings back memories of the original double-headed rail, because when the running head is worn out, the profile must be able to be turned over for a second use.

Do not think that the mentioned series is exhaustive, it would require books.

From 1856 onwards, steel increasingly replaced the wrought iron used until then. First for the most heavily loaded routes because it was much more expensive than iron, but as the price difference narrowed, for all applications. Because hard steel gives a longer life to the rails, but is also more susceptible to breakage, combinations of iron and steel came into use in the first half of the 20th century, but this did not affect the shape of the rails.

![[1528] [1528]](https://railfix.nl/wp-content/uploads/elementor/thumbs/1528-scaled-p3ksq4tgx1f1leyv695t2k58xcxkyhfgpgxyouo3jc.jpg)